Question :

With the increased globalisation, the Supply chain gained more importance and the area of logistics was modified and restructured. As with globalisation, the scope of activities and functions was expanded, to better manage them the logistics were restructured and scope was also expanded and renamed as Supply chain management. In, this article Woolworths a global retail Australian chain is taken to analyse the working and importance of Supply Chain on its effectiveness.

- What is Supply Chain Management?

- Understanding the importance of Supply Chain management on organisations effectiveness?

- Understanding how the Woolworth is applying this concept to gain a competitive advantage in its market and industry?

Answer :

The supply chain refers to the integration between the company and distributors which help in procuring the raw materials to making final product and services deliverable to end consumer and buyer effectively. The efficient work of the partners across the value chain helps in acquiring competitiveness by delivering it within minimal time. The supply chain management is the effective streamlining of all the business activities to maximise the customer value and achieve competitiveness. Supply chain activities cover the inception of activities related to the right from origin to point of consumption. The companies focus is to develop an efficient supply chain to lower the cost and achieve the economies of scale. Supply chain management aims to is to make the right product, available at the right price, right place and at right time. With the globalisation and rapid innovations in technology, the supply chain management acquired more light. The supply chain is not limited to the internal management of the activities it relates how the firm maintains its relationship with other interrelated companies also they also help in gaining the competitive advantage.

The Woolworths is an Australian retail chain, which remarked its performance through maintaining efficient grip over value chain activities which resulted in smooth flow of activities and helped them to increase their efficacy. The Woolworths is an largest retailing company and in financial and revenue terms the company is largest in Australia and second largest in New Zealand. The company major revenue is generated from its retail and supermarket segment.

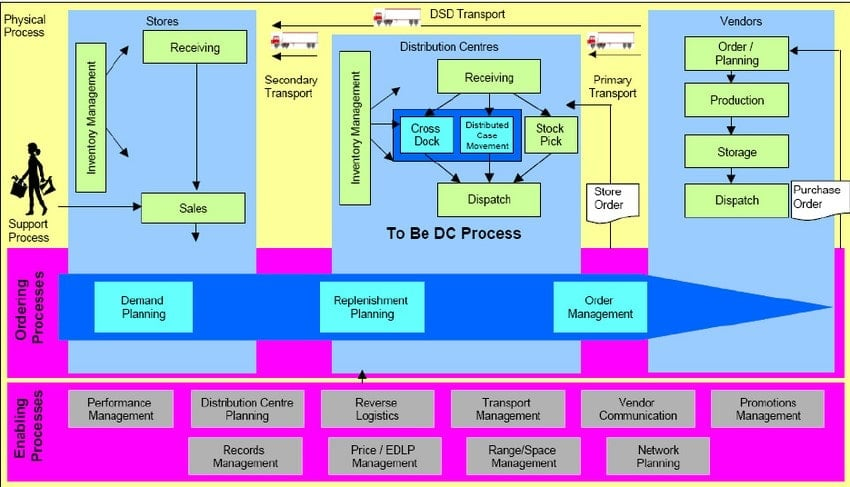

(Illustration 1: Woolworths Supply Chain System, 2021)

The company extracts full control over its supply chain operations and processes. The company connects through vendors and suppliers through the centrally equipped distribution centre. The equipment of the direct service delivery enables the suppliers and distributors to directly pick up and drop at the store location. This model enables the Woolworths to select reduced number of locations for catering distributing and selling both and help the company to focus on major functions by eliminating logistics and retailers function. This process enables the company to shorten their supply time and deliver on time. The company is favoured financially by eliminating the cost of distribution stations. By adopting this business process Woolworths, is able to develop the centralised distribution system which helped them to reduce the time of in between stacks, freight and storing cost.

In transportation management system the Woolworths gained all control of operations by themselves. The company by managing its logistics themselves, is able to improve on the delivery time. The company primary and supporting activities helps in moving the products from regional and national distribution centre to main store. By independently managing its logistics function Woolworths is benefited to handle and store the goods more safely. The cost of holding inventory will also be minimised helping the company to financially gain. The company even uses the Technology also to manage and monitor the operations more firmly. Woolworths uses such as the Electronic Data Interchange technique to increase its supply chain more efficient and effective.

Student may also like to read: Marketing Process and Activities: ALDI

The Woolworths supply chain director, Paul Graham motive is to design they supply chain in such a manner that it can save the extra cost and by saving the cost the items will be priced competitively to satisfy the consumer. The company by using the direct delivery method is able to eliminate the functions of warehouse and retailers to an large extent. By this application the company installed the everyday low pricing method. The Auto Smart rack system is used to inventory replenish software which updates the information automatically. With application of this technique the indicator of shelf display is connected automatically which equips the company electronically be sending notification when the rack is empty and in aces when there is over display also. This system also sends the e-messages to the vendors and suppliers in case the supply is not available with the company. By electronically connecting the informations the lead time between the inventory is reduced and everything functions smoothly. The company even uses the RFID and Bar coding technology to manage its operations. The unique code is being given to each object while in transit from thereon it can be tracked easily. The unique code being given helps in easily maintaining the database of objects and tracking its movement across the supply chain. The Barcode is given to items when it is being racked, the pricing details is being stored in that code. The scanning of this barcode is required at time of check out and automatically the bill is generated. With this application the Woolworths made an easy check out for the buyers by making ease and flexible for company and buyers dually.

Related Services: Online Assignment Writing Help

Therefore, the Woolworths success is credited to the centralised supply chain. This model of supply chain helped the company to lower the cost by eliminating its cost over various functions which were not adding to the synergy and capacity of supply chain. The adoption of such model helped the company to better manage its stock in transit. Therefore, the Woolworths supply chain management model is an exemplary model which helped them to reap the benefits and placed them the leader in retail industry by increasing its competencies and capacities. The company used the proper mix of technology and process to gain control over the activities in supply chain.

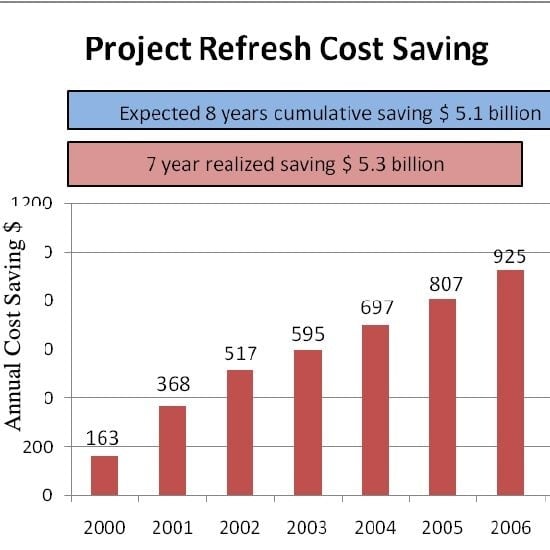

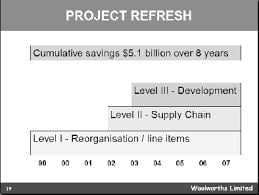

(Illustration 2: Woolworths Project Refresh Cost Saving, 2021)

The Woolworths has taken the Project Refresh in year 1999, with motive to redesign the supply chain and reap the benefit by exploiting the competencies with this restructuring. The company was complemented positively and gained huge success after conducting the modification in its supply chain structure. The Woolworths even used its value chain efficiency to achieve the competitive advantage in industry.

(Illustration 3: An Overview of Woolworths)